CASE STUDY

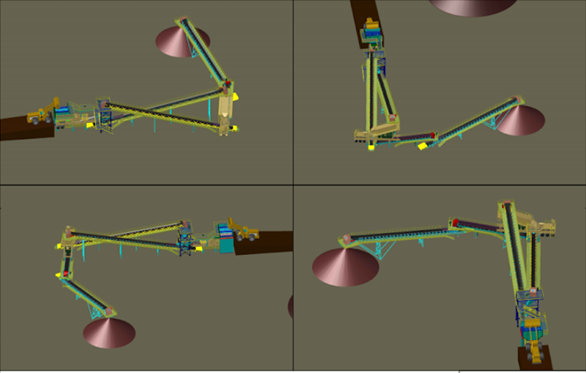

Mobile crushers are track-mounted rock crushing machines that are easily moved around and between production sites. This characteristic makes fire detection, alarming and suppression on such equipment a challenge.

They are widely used in aggregate production, recycling applications and mining operations. Mobile crushers can replace stationary crushing systems, which reduces the need for transportation and therefore reduces operating costs.

Among their fire risk areas are: the electric motors of the crushers, the conveyor belts and the area of electrical power panels.

Now, you'll find out what types of systems Elfire's fire engineering experts have designed for each of these risks.

Conheça nossa case de sucesso Britador Móvel...